Tech

Best Ways To Calculate Milling

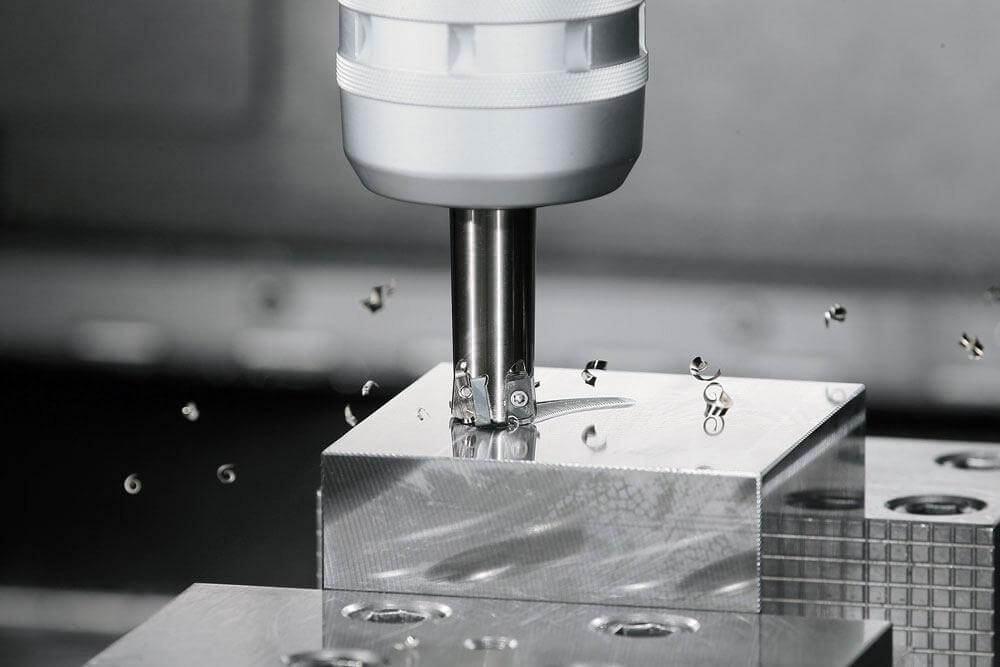

Few operations require more precision than milling. Having the right machine tools and other best practices allow the operator to get the perfect cut, which can be measured in small units such as millimeters or larger units such as feet or meters. A variety of milling machines and practices have helped society in recent decades.

Whenever you are working on a custom-made item that requires optimal accuracy, you should be using the finest tools and processes to achieve the best results. This includes a good understanding of calculating milling.

Precision Metrics

Machinists use a variety of methods to precisely measure how they shape items, whether it is a large piece or a finer object. To begin with, it is important to control the cutting speed of the tool. This comes down to a function of units of distance, such as surface feet per minute, across the workforce surface. Feed rate often expressed in inches per minute, is also critical, as this determines the velocity that the cutter penetrates the piece being shaped. Machinists also need to control other variables:

Feed per tooth

Adjusted feed per tooth or chip thinning

Tool diameter

Depth of cut

Width of cut

Number of teeth in cutter

A face mill cutter is a vital tool to have in your workshop. At Kennametal, we carry a large selection that allows you and your plant to shape an endless variety of items. This enables your company to cut into everything from stainless steel and cast iron to non-ferrous materials and high-temp alloys. You can choose the milling tool by several precision metrics, such as grade of cutting tool, cutting length, cutting diameter, and cutting edge.

Also Check: Top 8 Used Turf Machinery For Sale To Rely On For A Lush Green Course

Optimal Tools

At Kennametal, we strive to provide our suppliers with the tools needed to power modern society. Items such as metal cutting inserts are part of our product line. Performance inserts expand your capacity for boring, grooving, and facing, and we carry both positive and negative inserts. Quality inserts give you low-vibration cutting and enable your shop to get consistent results all of the time.

Inserts come in tungsten carbide-based materials that ensure the product will last a long time. Search filters allow you to find the tool with the ideal cutting length, feed rate and depth, grade of the tool, and other parameters.

You can also shop for economical tools that help your company’s bottom line while increasing its capacity for milling and cutting. You can buy discount insert milling cutter tools that expand available applications. HP carbide taps enable your machinists to perform precise milling and they come in a variety of configurations:

Straight flute

Spiral flute

Right-hand cut

Straight cylindrical

Powerful Engineering

The innovative tools you need for milling and cutting require the highest standards of engineering. That’s what you get with products from Kennametal. Premium tools reduce vibration and chatter and in some cases allow for higher feed rates, increasing productivity. Each tool comes with its own set of pros and cons and to learn more you can talk with one of our experts. Contact us today to discover the advantages of precision engineering.

Sources: https://www.engineeringchoice.com/types-of-milling-machines/

-

Business3 years ago

Business3 years agoHow to Do Long-Distance Moves with Children

-

Travel2 years ago

Travel2 years agoQuick Guide: Moving To Santa Rosa?

-

Real Estate3 years ago

Real Estate3 years agoWhy Dubai Festival City is a Great Neighbourhood for Young Learners

-

Business3 years ago

Business3 years agoIs Guest Posting a Good Inbound Marketing Strategy?

-

Business1 year ago

Business1 year agoThe Ultimate Guide To Thriving In Your Printing Franchise

-

Business1 year ago

Business1 year agoExploring The Benefits And Challenges Of Restaurant Franchising

-

Tech3 years ago

Tech3 years agoCyber Table That Will Change Your Life

-

Lifestyle1 year ago

Lifestyle1 year agoDallas’ Hidden Gems: 6 Must-Try Restaurants Off The Beaten Path!

Recent Comments