Information

What You Need To Know Before Buying A Pneumatic Pipe Cutter

If you’re interested in HVAC, you may have heard of a pneumatic pipe cutter. Pneumatic pipe cutters, or air-powered cutoff saws, are some of the most versatile tools today. They can cut through pipes and other materials with incredible precision.

But before you start digging into them, here are things to know.

Table of Contents

What Are Pneumatic Pipe Cutters?

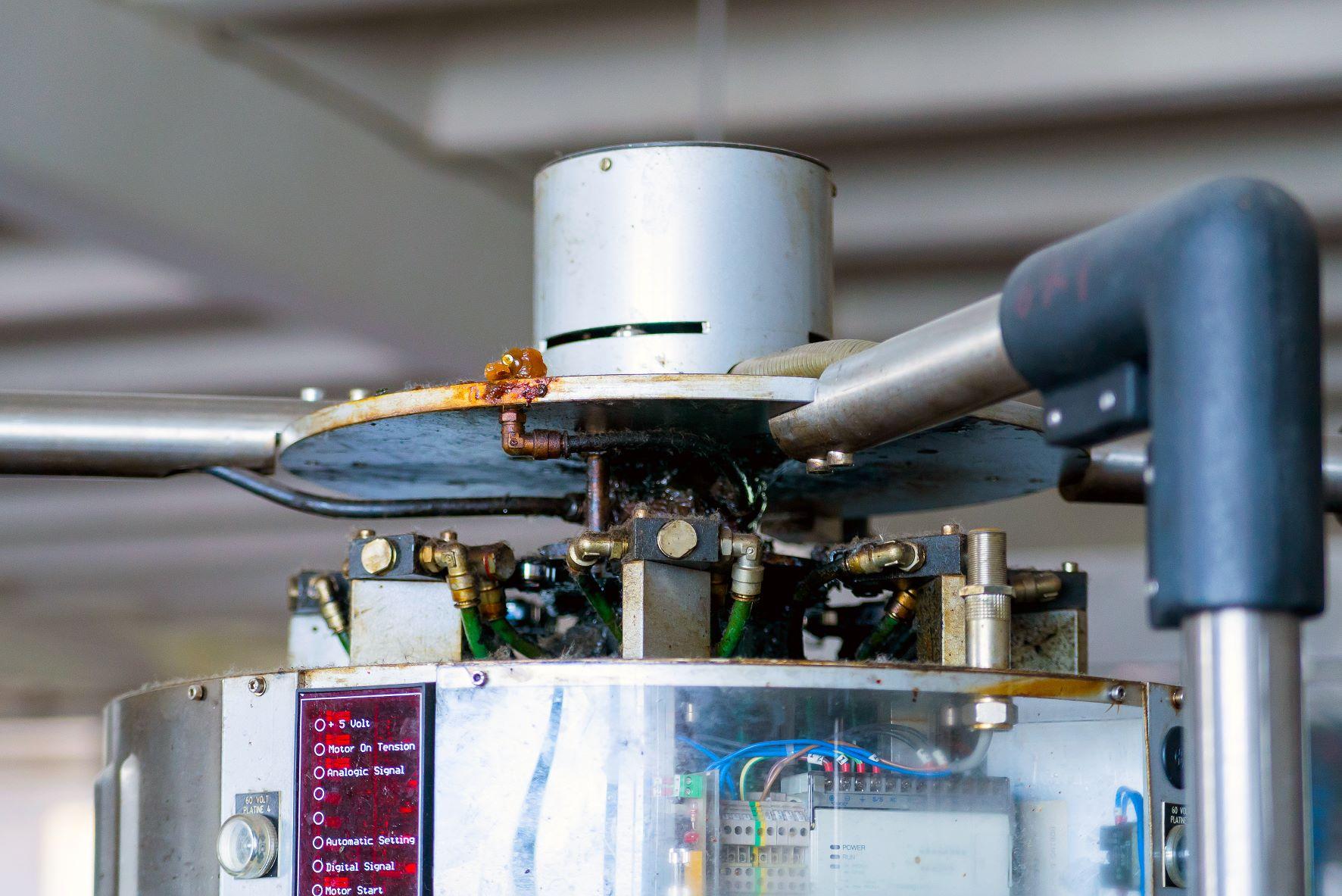

A pneumatic pipe cutter is a handheld cutting tool that uses compressed air to power its rotating blade. In this way, it’s similar to an electric circular saw but without the main electricity connection needed by many standard saws.

Unlike circular saws that use a chain drive mechanism to rotate the blade, pneumatic pipe cutters utilize compressed air (often called pressurized air) or gas such as nitrogen or carbon dioxide. These gases are typically stored in cylinders at high pressures before being released through hoses connected directly to your machine’s intake port.

What Do You Want To Cut?

If you’re unsure about what type of pipe you have or whether it’ll be hot, cold, or both when being cut, talk with your pipe distributor or go online to find out more. If you have insulated pipes, make sure the cutter can handle cutting through that material. You’ll also need to know the size of the pipes you’ll be cutting and whether they’re bent or straight and fastened in place.

Once you know what kind of cutter will get the job done for you, it’s on to budgeting and deciding how much your shop is willing to invest in one tool. A pneumatic pipe cutter price is determined by its heavy duty. Less expensive cutters can cost around USD$300 (US), while pneumatic units suitable for larger pipes used in industrial settings can run upwards of USD$4,000 (US). A good rule of thumb is to do your homework before buying so that you only buy once.

What Kind Of Pipe Cutter Do You Want?

Now, let’s move on to the various pneumatic pipe cutters available. These tools are designed to match different user needs, so it’s helpful to understand the differences.

A good cutter for plastic and metal pipes is an excellent choice if you need a versatile tool that can handle all sorts of pipes. For example, certain brands offer all-around performance in a handy package that is easy to maneuver around corners or tight spaces.

For workers who deal with substantial PVC pipes (greater than 20 inches in diameter), look for a cutter that includes an extension piece. You can reach the center of a big pipe without straining your back or impacting the cutter’s functionality. Some cutters provide just an extension and come with extra blades, so you don’t have to stop work too often.

Are Your Pipes Going To Be Piping Hot?

Before picking which pneumatic pipe cutter you want, you might ask yourself: What are the risks of using a pneumatic pipe cutter on a hot pipe to fix the water or get drains unblocked? The answer is that it depends. So how do you safely cut a hot pipe then? With a cold pipe cutter.

See, the cutting process works by applying pressure to two rotating wheels. These wheels press against each other, creating friction and allowing the operator to deploy an adjustable pivot arm with a blade at its end. As the pipe cutter is moved down the length of the pipe, this blade creates multiple cuts which are deep enough to divide through any material up to 2 inches thick. This adds to many different cuts being made in just one pass over your piping project.

In short, it’d be too hard for one person’s arms for them to make such deep cuts in many passes over their work if the pipes were cold. But if they’re already hot from handling something else, you’ll be able to manage.

Who Is Going To Use It?

To determine the type of pneumatic pipe cutter you’ll need, it’s essential to identify your experience and the level of involvement of those using it. If you’re new to the business, pneumatic pipe cutters with more complex features may be out of your realm. In this case, go for something more straightforward with fewer options.

Even if you have extensive experience and plan to use the machine yourself, consider that those other employees may use it regularly for their projects. Choosing a cutter that requires little training and experience will allow others to use it, which may increase productivity.

If you don’t have enough employees to manage multiple machines at once or don’t want to spend money on paying numerous operators, consider a bigger machine that can handle any size project. When taking on large jobs, you won’t have to worry about running out of space or needing additional operators.

How Easy And Safe Is It To Operate?

Most pipe cutters work the same way. After replacing the shear blade, you’ll add a few drops of cutting oil to the oil reservoir and turn on your pneumatic pipe cutter. Once it’s running, place the head of the cutter on top of your pipe and set it so that it’s parallel to the ground. To cut, press down on the foot pedal while maintaining a firm grip on your pipes. That’s how easy everything should go.

The last thing you need to keep in mind is that these tools are loud. They can be dangerous if not used correctly—but they’re also extremely loud. When using a pneumatic pipe cutter, you should always wear ear protection (or any other type of power tool, for that matter).

Also, Check – Sports Betting Explores Metaverse Experiences

Conclusion

In this article, you learned about pneumatic cutters and got a head start knowing your options. Before purchasing a pipe cutter, consider what you require and which pipe cutter will provide you with the best value for your money. Also, don’t forget to look into other people’s experiences with these tools. Ask your friends if they have any experiences they would like to share with you.

-

Business3 years ago

Business3 years agoHow to Do Long-Distance Moves with Children

-

Travel2 years ago

Travel2 years agoQuick Guide: Moving To Santa Rosa?

-

Real Estate3 years ago

Real Estate3 years agoWhy Dubai Festival City is a Great Neighbourhood for Young Learners

-

Business3 years ago

Business3 years agoIs Guest Posting a Good Inbound Marketing Strategy?

-

Business1 year ago

Business1 year agoThe Ultimate Guide To Thriving In Your Printing Franchise

-

Business1 year ago

Business1 year agoExploring The Benefits And Challenges Of Restaurant Franchising

-

Tech3 years ago

Tech3 years agoCyber Table That Will Change Your Life

-

Lifestyle1 year ago

Lifestyle1 year agoDallas’ Hidden Gems: 6 Must-Try Restaurants Off The Beaten Path!

Recent Comments